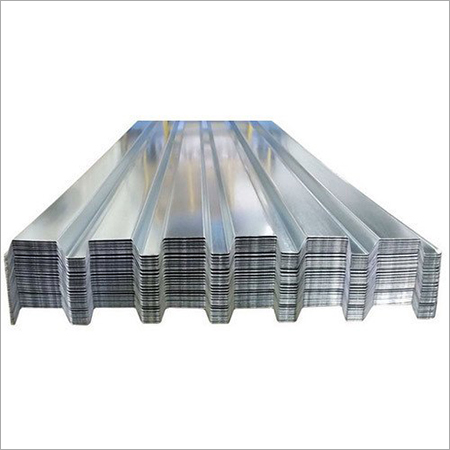

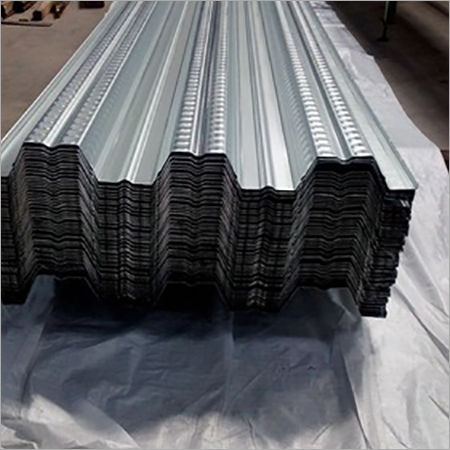

Steel Decking Sheet

Price 500 INR/ Square Meter

Steel Decking Sheet Specification

- Height

- 50 mm to 76 mm (rib height)

- Surface Treatment

- Galvanized/Zinc Coated

- Roof Material

- Galvanized Steel

- Usage & Applications

- Multi-storey buildings, Bridges, Industrial sheds, Mezzanine floors

- Features

- Lightweight, Easy Installation

- Technics

- Cold Rolled

- Material

- Galvanized Steel

- Tile Material

- Steel

- Tile Type

- Decking Sheet

- Type

- Steel Decking Sheet

- Size

- Customizable (commonly 1000 mm effective coverage)

- Shape

- Trapezoidal

- Pattern

- Corrugated

- Heat Transfer Coefficient

- Low thermal conductivity suitable for roofing and flooring

- Thickness

- 0.8 mm to 2.0 mm

- Length

- Upto 12 meters or as per customer requirement

- Width

- 900 mm to 1250 mm (overall), 1000 mm (effective)

- Span Capacity

- Up to 3.5 meters (depending on load and profile)

- Forming Process

- Roll Formed

- Compatibility

- Compatible with concrete and steel structures

- Color Options

- Silver (standard), can be painted/coated

- Edge Type

- Square and overlap edge available

- Rust Resistance

- High due to zinc coating

- Load Capacity

- Depends on thickness and profile, typically supports 1.5-2.5 kN/m2

- Fire Resistance

- Non-combustible

- Yield Strength

- 245-345 MPa

- Noise Reduction

- Moderate sound insulation properties

- Maintenance

- Low maintenance

- Coating Mass

- 120 GSM or customized

Steel Decking Sheet Trade Information

- Minimum Order Quantity

- 500 Square Meters

- Supply Ability

- 100 Square Meters Per Month

- Delivery Time

- 1 Week

About Steel Decking Sheet

Steel Decking Sheet is an industrial-grade reinforcement floor cover that is widely used in heavy engineering industries to provide extra strength and durability to withstand impacts of heavy impact loads and vibrations. This deck sheet is provided with a textured design that offers good friction to prevent accidents due to slipping. The steel used in the manufacturing of the offered Steel Decking Sheet is provided with a silver-colored non-corrosive coating that adds extra service life.

Specification

| Surface Treatment | Galvanized |

| Thickness | 0.8 mm, 1 mm, 1.2 mm |

| Color | White |

| Material | Steel |

| Area Of Application | Residential & Commercial |

| Manufacturing Technique | Cold Rolled |

Exceptional Strength and Rust Resistance

Manufactured using cold-rolled, galvanized steel with a yield strength between 245 and 345 MPa, these steel decking sheets deliver both durability and performance. The zinc coating, customizable up to 120 GSM, dramatically enhances resistance to corrosion, making them suitable for long-term structural applications in demanding environments.

Versatile Applications and Easy Installation

The trapezoidal, corrugated profile of these sheets not only provides superior load-bearing capacity but also simplifies the installation process. With effective coverage widths of 1000 mm and customizable lengths up to 12 meters, they are ideal for a diverse range of projects, from industrial sheds to multi-storey commercial buildings across India.

Safety and Comfort Features

Engineered for fire safety, steel decking sheets are non-combustible. Their low thermal conductivity minimizes heat transfer, while moderate sound insulation properties contribute to a quieter indoor environment. These features ensure both safety and comfort for building occupants, making them a reliable choice for modern construction.

FAQ's of Steel Decking Sheet:

Q: How are steel decking sheets installed in construction projects?

A: Steel decking sheets are typically fixed to supporting beams or structures using self-drilling screws or welds. Their lightweight design and roll-formed edges facilitate quick alignment and secure placement, making installation both efficient and straightforward.Q: What applications are steel decking sheets most suitable for?

A: These sheets are ideal for use in multi-storey buildings, bridges, industrial sheds, mezzanine floors, and various roofing and flooring systems. Their compatibility with both concrete and steel structures makes them highly versatile across different construction needs.Q: When should customized sizes or coatings be chosen for decking sheets?

A: Customized sizes or coatings should be selected based on specific project requirements, such as span capacity, environmental exposure, or architectural preferences. For example, higher coating mass or custom lengths may be chosen to enhance durability in corrosive environments or to match design specifications.Q: Where can steel decking sheets be used within a building?

A: Steel decking sheets can be used in floors, roofs, or as permanent formwork in civil and industrial buildings. Their adaptability allows integration into new constructions or renovations, providing structural support and enhancing load distribution.Q: What process is involved in manufacturing these steel decking sheets?

A: The sheets are manufactured using a cold rolling process, followed by zinc galvanization. They are then roll-formed into a trapezoidal corrugated pattern, with edges that can be square or overlap, ensuring both strength and straightforward installation.Q: How does the yield strength and coating mass benefit the user?

A: High yield strength (245-345 MPa) allows the sheets to support significant loads, while the zinc coating of up to 120 GSM ensures lasting rust resistance. Together, these characteristics provide long structural life, reduced maintenance, and safer applications.Q: What maintenance is required for steel decking sheets?

A: Steel decking sheets require minimal maintenance due to their galvanized surface, which protects against rust and environmental wear. Routine inspections and occasional cleaning are usually sufficient to preserve their performance and appearance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Decking Sheets Category

Roof Decking Sheet

Price 60 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Material : Other, Galvanized Iron (GI)

Shape : Trapezoidal

Roof Material : GI Steel

Pattern : Corrugated

Floor Decking Sheet

Price 60 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Material : Other, Galvanized Steel

Shape : Trapezoidal

Roof Material : Steel

Pattern : Corrugated

GI Decking Sheet

Price 70 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Material : Iron

Shape : Rectangular

Roof Material : GI

Pattern : Galvanized

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry