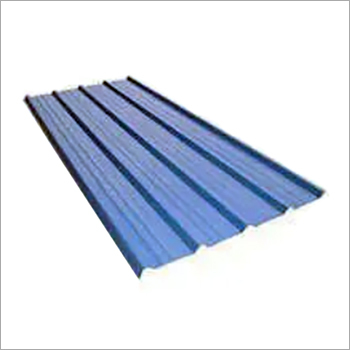

Curved Roofing Sheet

Curved Roofing Sheet Specification

- Material

- Color coated sheet

- Type

- Roofing Sheet

- Shape

- Curved

- Thickness

- 2-10 Millimeter (mm)

- Width

- 1250-1500 Millimeter (mm)

Curved Roofing Sheet Trade Information

- Minimum Order Quantity

- 50 Sheets

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- Sheet

- Delivery Time

- Days

- Main Domestic Market

- All India

About Curved Roofing Sheet

Familiar as chief supplier, we are appreciated for presenting an excellent array of Curved Roofing Sheet. The available range is acknowledged for durable and maintenance free functioning. Specially designed range is manufactured with the aid of concealed clip and panels that are seamed together with the help of machine. Our sheets have wide usage in agriculture sector, warehousing and numerous industries due to unrivaled qualities like sturdy built, perfect ventilation, attractive appearance, simple installation, corrosion proof and galvanized surface. We are presenting these Curved Roofing Sheet in beautiful colours and dimensions at nominal rates.

Specification

| Minimum Order Quantity | 500 Square Meter |

| Brand | Balaji Roofing |

| Thickness of Sheet | 2-10 mm |

| Surface Treatment | Color Coated |

| Features | Water Proof, Corrosion Resistant |

| Material | Steel / Stainless Steel |

| Manufacturing Technique | Cold Rolled |

| Application Areas | Construction, Roofing, Car Parking, Commercial Buildings and Warehouses |

| Width | 1020 mm |

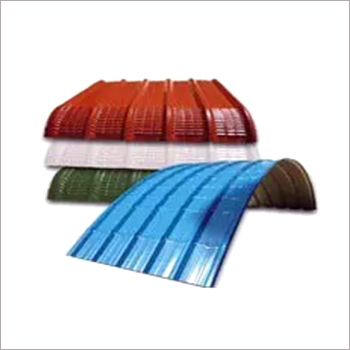

Durable and Stylish Curved Roofing Solutions

Curved roofing sheets provide an elegant and efficient roofing option. Made from robust color-coated material, these sheets offer outstanding resistance to weather elements and rust. Their curved design not only improves the aesthetics of any structure but also promotes better water drainage and wind deflection. With a focus on high performance, these sheets are a reliable investment for lasting durability.

Expert Supply and Installation Services Across India

As a leading supplier, trader, and service provider in India, we offer comprehensive solutions for curved roofing sheet requirements. Our team assists with product selection, ensures timely delivery, and manages professional installation. By leveraging our industry experience, clients receive support from the initial consultation through project completion, guaranteeing satisfaction and exceptional roofing performance.

FAQs of Curved Roofing Sheet:

Q: How are curved roofing sheets installed on a building?

A: Curved roofing sheets are installed using specialized mounting systems that secure the sheets to the roof structure. The process typically involves aligning the curved panels, fastening them with corrosion-resistant fasteners, and sealing joints to prevent leaks. Professional installation is recommended to ensure a precise fit, structural safety, and optimal functionality.Q: What is the main benefit of using color-coated curved roofing sheets?

A: Color-coated curved roofing sheets offer superior durability and resistance to corrosion, making them ideal for Indian climates. The color coating also enhances the sheets appearance, adds a protective barrier against UV rays, and ensures long-lasting performance with minimal maintenance.Q: When should I consider choosing a curved roofing sheet over a flat one?

A: Curved roofing sheets are most suitable when your project demands a combination of aesthetic appeal and efficient water runoff. These sheets are commonly used for auditorium roofs, warehouses, commercial complexes, and modern residential spaces desiring a distinctive look and reliable weather protection.Q: Where are curved roofing sheets commonly used in India?

A: Curved roofing sheets are widely used in various sectors across India, including industrial plants, shopping malls, schools, sports arenas, and even some residential buildings. Their adaptability and attractive appearance make them a popular choice for both new constructions and renovations.Q: What materials are used in these curved roofing sheets?

A: Our curved roofing sheets are manufactured from high-grade color-coated steel sheets, ensuring strength, longevity, and resistance to harsh environmental conditions. The color coating provides an added layer of protection while offering multiple aesthetic options.Q: What is the typical process to order and receive curved roofing sheets from your company?

A: Clients can initiate the process by contacting our sales team with project specifications. We provide guidance on selecting the right size and thickness, after which a quotation and delivery timeline are shared. Once the order is confirmed, we coordinate manufacturing, delivery, and optional installation services, ensuring a smooth and timely experience.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roofing Sheet Category

Color Coated Steel Roofing Sheet

Price 290 INR / Square Meter

Minimum Order Quantity : 50 Square Meters

Pattern : Color Coated

Material : Other, Metal

Shape : Rectangular

Thickness : 210 Millimeter (mm)

Curved Metal Roofing Sheet

Price 120 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Pattern : Wave

Material : Other

Shape : Curved

Thickness : 210 Millimeter (mm)

Colour Coated Roofing Sheet

Price 950 INR / Square Meter

Minimum Order Quantity : 50 Sheets

Pattern : Wave

Material : Other, Mild Steel

Shape : Rectangular

Thickness : 210 Millimeter (mm)

Roofing Cladding Sheet

Price 250 INR / Square Meter

Minimum Order Quantity : 500 Square Meters

Pattern : Plain

Material : Other, GI

Shape : Rectangular

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry